The Silent Threat: Fake Titanium Parts in Aircraft Manufacturing

The Silent Threat: Fake Titanium Parts in Aircraft Manufacturing.

In the world of aviation, safety is paramount. Every component of an aircraft is meticulously designed, manufactured, and tested to ensure the highest standards of reliability and performance. However, a growing and concerning issue has emerged in recent years: the infiltration of fake titanium parts into the supply chain of aircraft manufacturers. This alarming trend poses serious risks to aviation safety, prompting a need for immediate attention and action.

The Importance of Titanium in Aviation

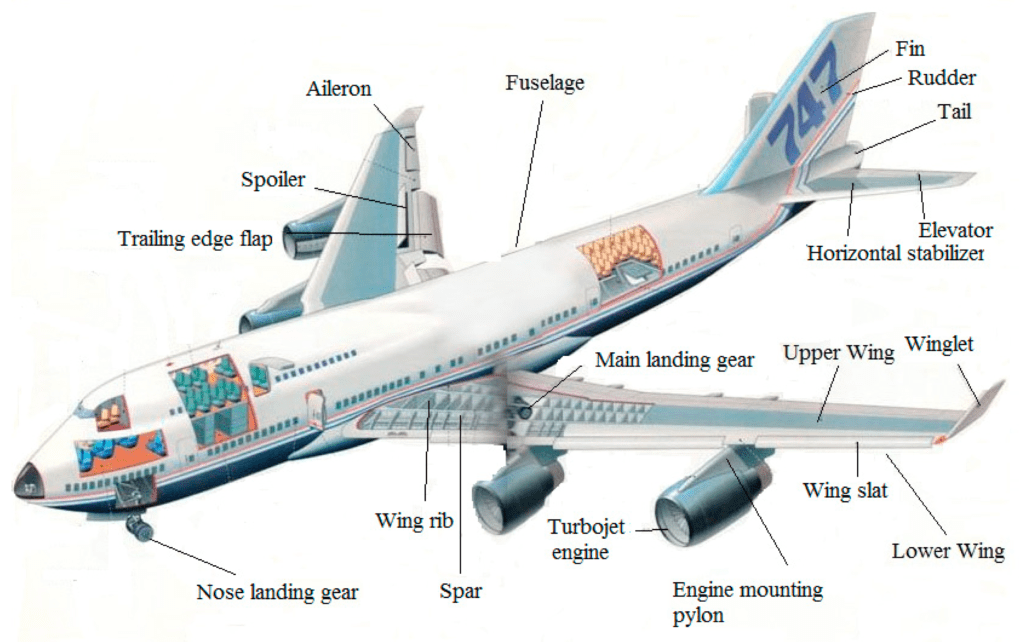

Titanium is a critical material in the aerospace industry due to its exceptional strength-to-weight ratio, corrosion resistance, and ability to withstand extreme temperatures. These properties make it ideal for various aircraft components, including engines, airframes, and landing gear. The use of high-quality titanium parts is crucial for maintaining the structural integrity and overall safety of aircraft.

The Infiltration of Counterfeit Parts

Despite stringent quality control measures, counterfeit titanium parts have found their way into the supply chains of major aircraft manufacturers. These fake parts often come from unscrupulous suppliers who exploit gaps in the procurement processes to introduce substandard materials. The counterfeit components are usually manufactured using lower-grade titanium or alternative materials that do not meet the stringent specifications required for aerospace applications.

One notable incident involved A&P Alloys, a Massachusetts-based company, which sold uncertified titanium to a number of aerospace manufacturers, including Boeing and Airbus. The titanium was falsely certified, leading to a major recall and an extensive investigation by the U.S. Department of Justice .

The Risks Posed by Counterfeit Titanium

The use of counterfeit titanium parts can have catastrophic consequences. These components may not endure the stresses and strains experienced during flight, leading to potential failures. The risks include structural weaknesses, engine malfunctions, and other critical failures that could result in accidents. Even minor discrepancies in material properties can lead to significant safety hazards when multiplied across thousands of parts in an aircraft.

Detection and Prevention Measures

To combat the threat of counterfeit parts, the aerospace industry has implemented several measures:

- Stringent Supplier Vetting: Aircraft manufacturers have intensified the vetting process for their suppliers, ensuring that only reputable and certified sources are used. This involves thorough background checks and regular audits.

- Advanced Testing and Inspection: Enhanced testing procedures, such as X-ray fluorescence (XRF) and ultrasonic testing, are employed to verify the authenticity and quality of titanium parts. These tests help identify discrepancies in material composition and structural integrity.

- Blockchain Technology: Some companies are exploring the use of blockchain technology to create a secure and transparent supply chain. Blockchain can provide an immutable record of each part’s origin, manufacturing process, and certification, making it easier to trace and verify components.

- Collaboration and Reporting: The industry encourages collaboration between manufacturers, suppliers, and regulatory bodies to share information about suspected counterfeit parts. Reporting mechanisms are in place to alert other stakeholders about potential threats.

Regulatory and Legal Actions

Governments and regulatory bodies have taken steps to address the issue of counterfeit parts. In the United States, the Federal Aviation Administration (FAA) has implemented strict regulations and penalties for suppliers found guilty of distributing counterfeit materials. Legal actions against offending companies and individuals serve as a deterrent and highlight the seriousness of the issue.

For instance, the case against A&P Alloys resulted in significant fines and prison sentences for those involved. This legal action underscores the commitment of regulatory bodies to uphold the integrity of the aerospace supply chain .

Conclusion

The infiltration of fake titanium parts into the supply chains of aircraft manufacturers is a serious threat that cannot be overlooked. Ensuring the safety and reliability of aircraft requires a concerted effort from all stakeholders in the aviation industry. By implementing rigorous testing, adopting advanced technologies, and fostering collaboration, the industry can mitigate the risks posed by counterfeit parts. Vigilance and proactive measures are essential to maintaining the high standards of safety that the aviation sector demands.

We at Soni Steels provide ONLY certified tested materials to our customers, though our products are centered around Special Alloys & Steel, we understand our customers need for referenceable quality materials. You can see our stocks here…..

References

- Bloomberg. (2023). “Fake Titanium: How A&P Alloys Tricked the Aerospace Industry”. Retrieved from Bloomberg.

- U.S. Department of Justice. (2023). “Massachusetts Company and Owners Plead Guilty to Supplying Substandard Titanium to Aerospace Industry”. Retrieved from Justice.gov.

- FAA. (2023). “Regulations and Enforcement: Ensuring Quality in Aerospace Materials”. Retrieved from FAA.gov.