Why is Tool steel important for Electronics

Let’s delve into the fascinating world of tool steel and its crucial role in the manufacturing of electronics chips.

1. Introduction to Tool Steel

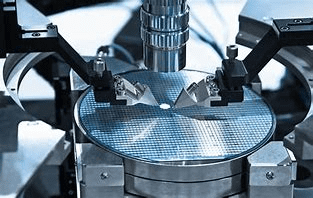

Tool steel is a type of high-quality carbon and alloy steel specifically designed for creating tools and dies used in manufacturing processes. These materials exhibit exceptional hardness, resistance to wear, and toughness. As a matter of fact, when it comes to electronics chips, tool steel plays a pivotal role in various aspects of their production.

2. Key Applications of Tool Steel in Electronics Chips

Here are some ways in which tool steel contributes to the manufacturing of electronics chips:

- Mold Making: Tool steel molds are especially essential for shaping and forming electronic components. Whether it’s creating intricate patterns on printed circuit boards (PCBs) or producing connectors, tool steel ensures accuracy and durability. These molds are often machined from materials like aluminum, P20 tool steel, or NAK80 steel1.

- Stamping and Forming: Tool steels are used for metal stamping, forming, and shearing processes during chip production. Their undeniable hardness and wear resistance ensure precise and consistent results. From lead frames to delicate chip components, tool steel plays a critical role.

- Cutting Tools: High-speed tool steels find applications in cutting tools used during PCB fabrication, precision machining, and assembly. These tools maintain their sharp edges even under demanding conditions, ensuring clean cuts and precise dimensions.

3. Heat Treatment and Precision

Tool steels are typically heat treated to increase their hardness and wear resistance. Their ability to maintain precision dimensions even at elevated temperatures makes them ideal for chip production. Whether it’s etching intricate circuits or molding tiny components, tool steel ensures consistent results.

4. Examples of Specific Components Made with Tool Steel

Here are some specific electronic components that rely on tool steel:

- Lead Frames: These thin metal frames provide electrical connections for semiconductor chips. Tool steel molds are used to create precise lead frame shapes.

- Connector Housings: Tool steel ensures the durability and accuracy of connector housings, which house connectors for various electronic devices.

- PCB Drills and Milling Cutters: High-speed tool steels are employed to create drills and milling cutters used in PCB fabrication.

- Die Components: Tool steel dies shape and form components such as transistors, capacitors, and resistors.

5. Conclusion

Next time you use your smartphone or any electronic gadget, appreciate the craftsmanship of tool steel that went into its creation. Behind every sleek chip lies the precision and durability of these specialized steels! 🛠️

If you would like to know about the TESTED tool steels that we stock just click here to know more

References:

- All About Tool Steel: Definition, Types, and Uses

- Tooling in Electronics Manufacturing | SEACOMP

- Tool Steels – EngineeringTechnology.org

- Tool Steel Market: Modern Tool Steel Manufacturing

I hope you find this article informative! If you have any further questions or need additional details, feel free to reach out to us